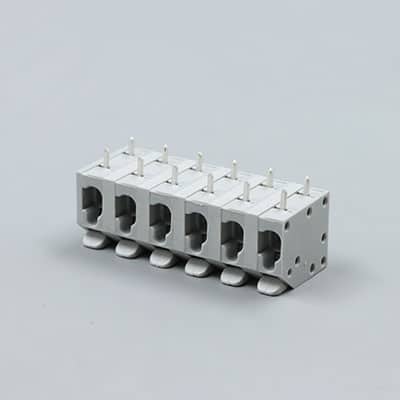

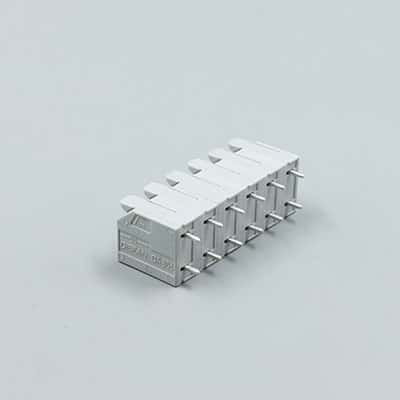

The spring terminal block (also known as spring clamp terminal block, spring terminal connector) clamps the wires by using springs, and is suitable for applications with small wire diameters and no high-strength connection requirements, or used in environments where the operating space is relatively narrow.

SCONDAR provides 2.5mm, 2.54mm, 3.5mm, 4.0mm, 4.6mm, 5mm, 10mm pitch, 2 pin to 24 pin PCB spring terminal block, If you didn’t find the PCB spring terminal block connector you want, welcome to contact us for help.

SCT250A-2.50-xxB1650

- Pitch: 2.5mm

- Rated voltage: 300V/250V

- Rated surge voltag: 2KV

- Rated current: 2A/2A

- Conductor cross section: 24~20AWG

- Strip length: 9mm

- Ambient temperature: -40℃~105℃

SCT250A-3.50-xxB1650

- Pitch: 3.5mm

- Rated voltage: 320V/300V

- Rated surge voltag: 4KV

- Rated current: 8A/10A

- Conductor cross section: 22~16AWG

- Strip length: 9mm

- Ambient temperature: -40℃~105℃

SCT803R-3.50-XXB1658

- Pitch: 3.5mm

- Rated voltage: 250V

- Impulse withstand voltage: 4KV

- Rated current: 10A

- Conductor cross section: 24~16AWG

- Strip length: 8-9mm

- Ambient temperature: -40℃~105℃

SCT803R-5.00-XXB1658

- Pitch: 5.0mm

- Rated voltage: 300V

- Impulse withstand voltage: 4KV

- Rated current: 15A

- Conductor cross section: 24~14AWG

- Strip length: 8-9mm

- Ambient temperature: -40℃~105℃

SCT806R-7.50-XXB1658

- Pitch: 7.5mm

- Rated voltage: 450V

- Impulse withstand voltage: 4KV

- Rated current: 32A

- Conductor cross section: 22~12AWG

- Strip length: 10-11mm

- Ambient temperature: -40℃~105℃

SCT806V-7.50XXB1658

- Pitch: 7.5mm

- Rated voltage: 450V

- Impulse withstand voltage: 4KV

- Rated current: 32A

- Conductor cross section: 22~12AWG

- Strip length: 10-11mm

- Ambient temperature: -40℃~105℃

SCT807R-7.50-XXB1658

- Pitch: 7.5mm

- Rated voltage: 450V

- Impulse withstand voltage: 4KV

- Rated current: 41A

- Conductor cross section: 22~10AWG

- Strip length: 10-11mm

- Ambient temperature: -40℃~105℃

Spring terminal blocks are essential components in electrical connections, providing a reliable and efficient method for connecting wires without the need for screws. They are especially valued for their ease of use and maintenance-free design, making them a popular choice in various applications.

How Spring Terminal Blocks Work

Spring terminal blocks operate using a spring mechanism to hold wires securely. When a wire is inserted into the terminal, a spring clamps around it, ensuring a firm and stable connection. To insert or remove a wire, you use a lever or push-button to open the spring, allowing for quick and straightforward wire handling. This design eliminates the need for manual tightening, which can be prone to loosening over time.

Key Features

- Quick and Tool-Free Connection: Wires can be connected easily without any special tools, reducing installation time and effort.

- Vibration Resistance: The spring mechanism holds the wire firmly in place, making the connection resistant to vibrations and movement, which is particularly useful in industrial settings.

- Maintenance-Free: Unlike screw terminals, spring terminal blocks do not require regular adjustments or tightening, minimizing maintenance needs.

- Compact and Efficient: Many spring terminal blocks are designed to be compact, allowing for space-saving in wiring setups while maintaining high efficiency.

- Reliable and Long-Lasting: The spring’s consistent pressure ensures a reliable connection, reducing the risk of contact failure and improving overall durability.

Applications

Spring terminal blocks are widely used in various industries and settings, including:

- Industrial Automation: They are employed in control panels, machinery, and automation systems where reliable and quick connections are critical.

- Building Wiring: Ideal for use in electrical distribution systems, lighting control, and HVAC systems in commercial and residential buildings.

- Electrical Equipment: Common in devices and equipment where secure and stable connections are necessary for optimal performance.

Conclusion

Spring terminal blocks offer a robust and user-friendly solution for electrical wiring. Their design, which uses a spring to secure connections, provides advantages such as ease of installation, resistance to vibration, and minimal maintenance. These features make them a valuable choice for a wide range of applications, ensuring reliable and efficient electrical connections.