At Scondar, we specialize in providing a wide array of high-quality pin headers and female header connectors tailored to meet the unique needs of our customers. From standard configurations to advanced designs such as elevated pin headers, double-sided plastic right-angle elevated pin headers, U-shaped pin headers, and multi-row pin headers, our extensive product range covers various pitch sizes (1.0mm, 1.27mm, 2.0mm, and 2.54mm) and mounting types (vertical, right-angle, through hole, and SMD). Our expert engineers collaborate with you to create custom solutions, ensuring precision and reliability. Trust Scondar for innovative, top-tier connector solutions for your next project.

Custom Pin Header Connector

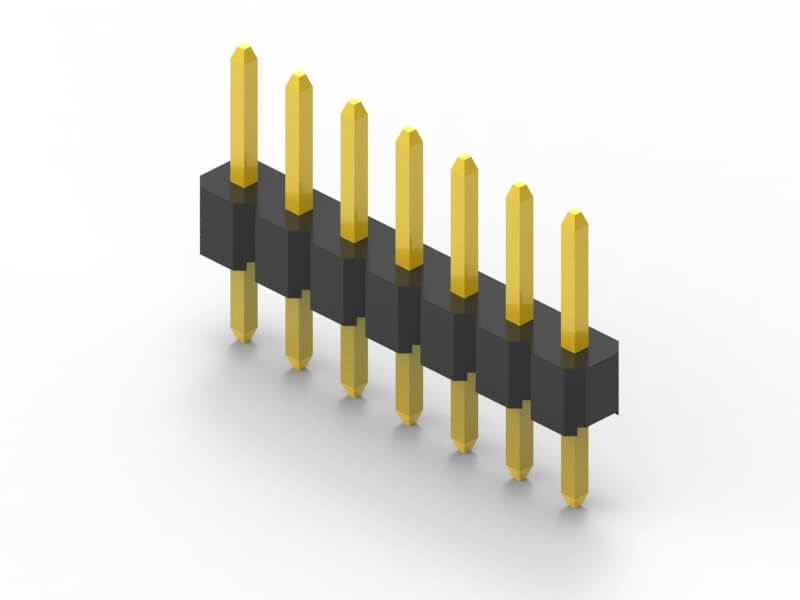

Pin Header

Through Hole Pin Header

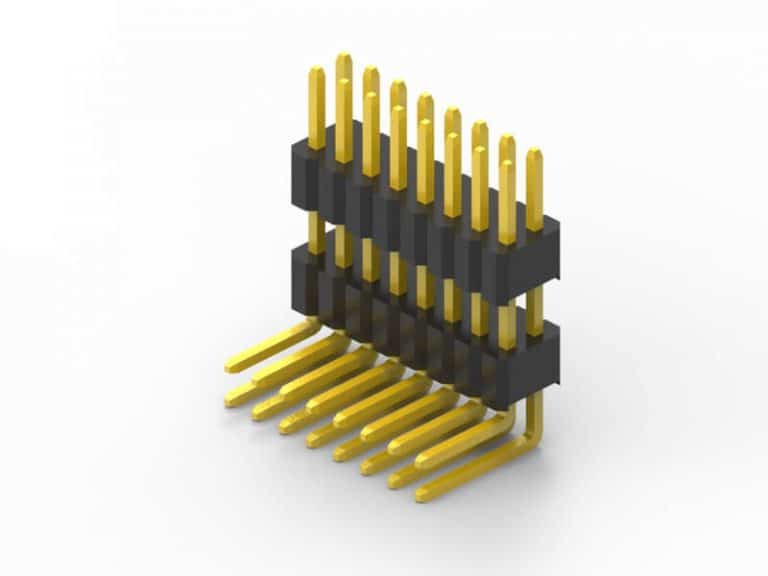

Right-Angle THT Pin Header

Pin Header

Right-Angle SMD Pin Header

Through Hole Pin Header

Through Hole Pin Header

Through Hole Pin Header

Pin Header

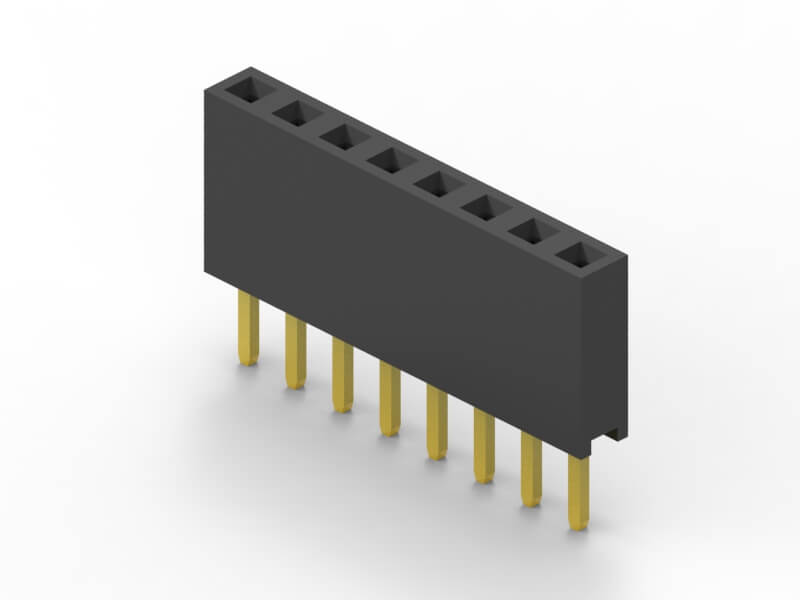

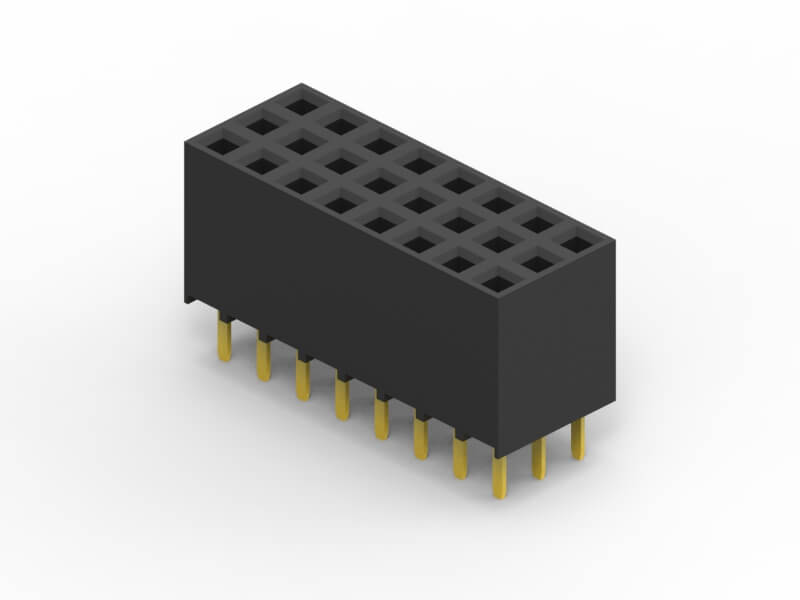

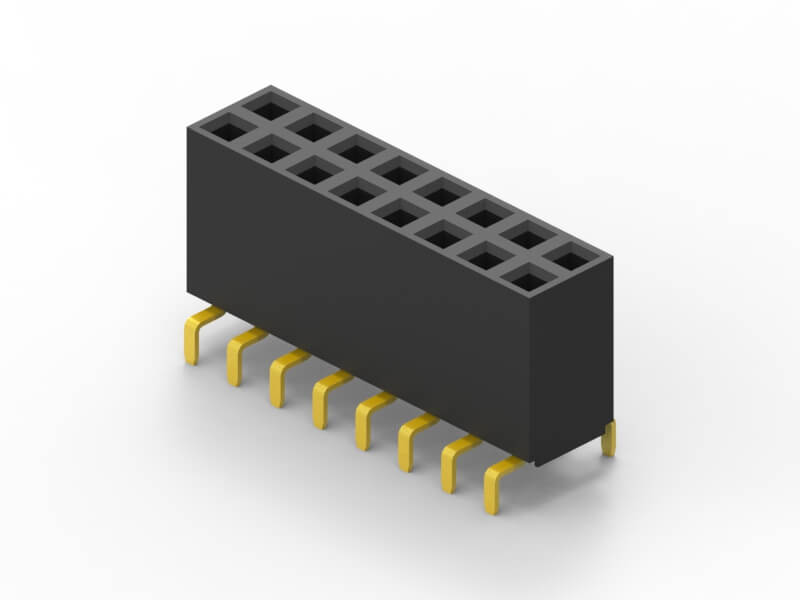

Custom Female Header Connector

Through Hole Female Header

Female Header

Custom Pin Header and Female Header Connector Solutions by Scondar

Diverse Header Connector Options

At Scondar, we pride ourselves on offering a wide variety of pin headers and female header connectors to meet the specific needs of our customers. Beyond the common forms, we provide unique shapes and configurations, including:

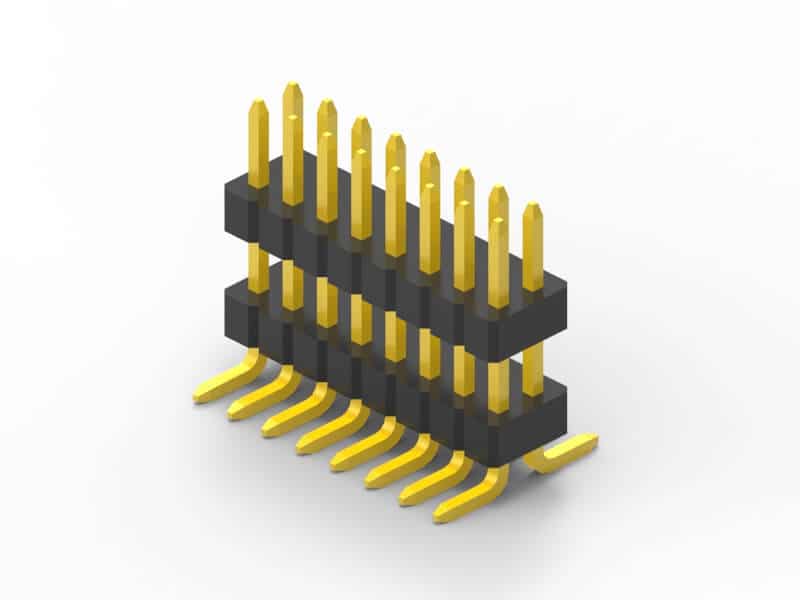

Elevated Pin Header

Elevated pin headers feature dual layers of plastic, raising the pins above the board for better clearance and connectivity options.

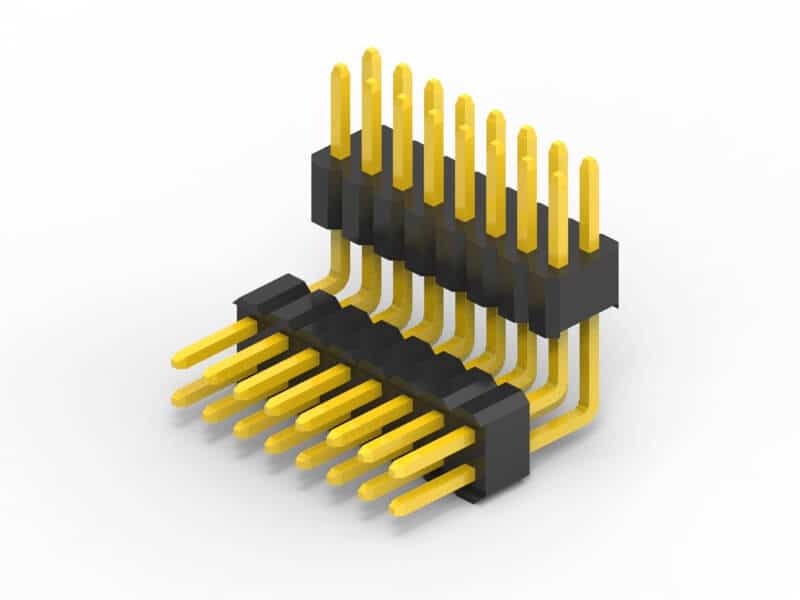

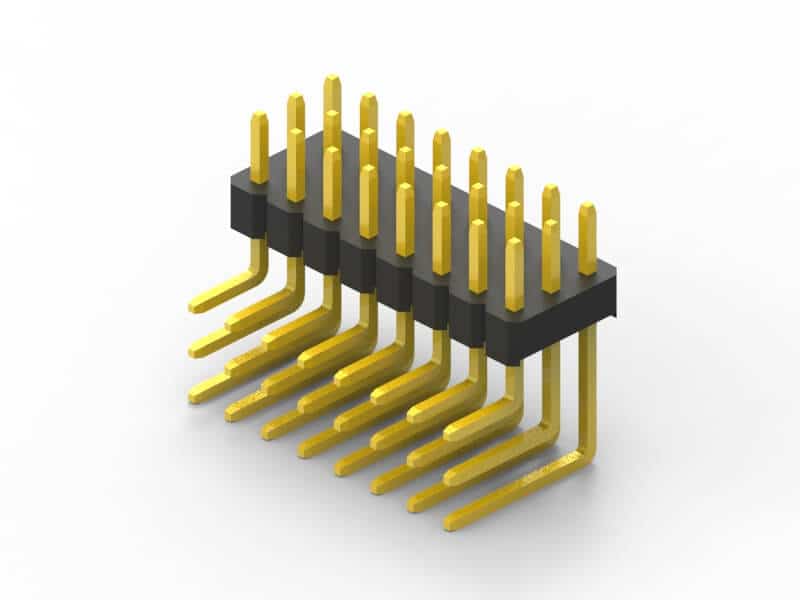

Double-Sided Plastic Right-Angle Elevated Pin Header

This design includes plastic on both sides and a right-angle bend, combined with elevated pins, to provide versatile mounting and connection capabilities.

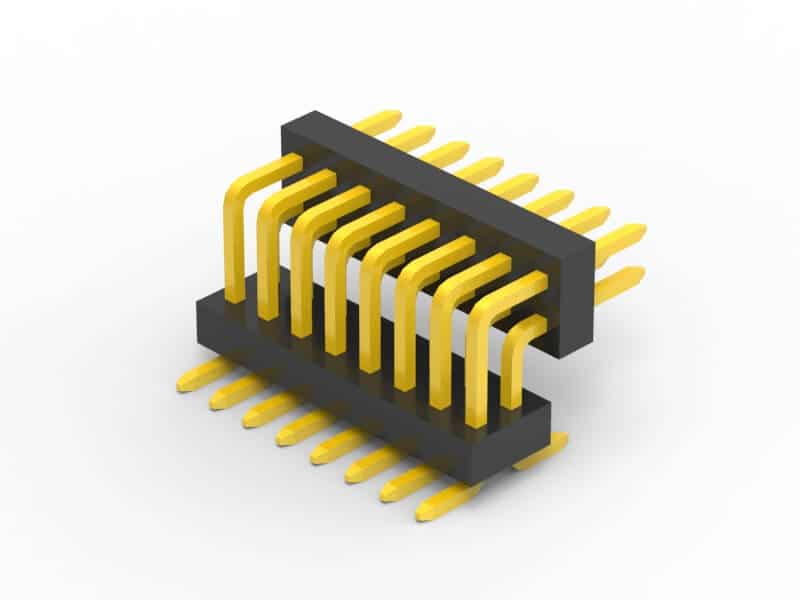

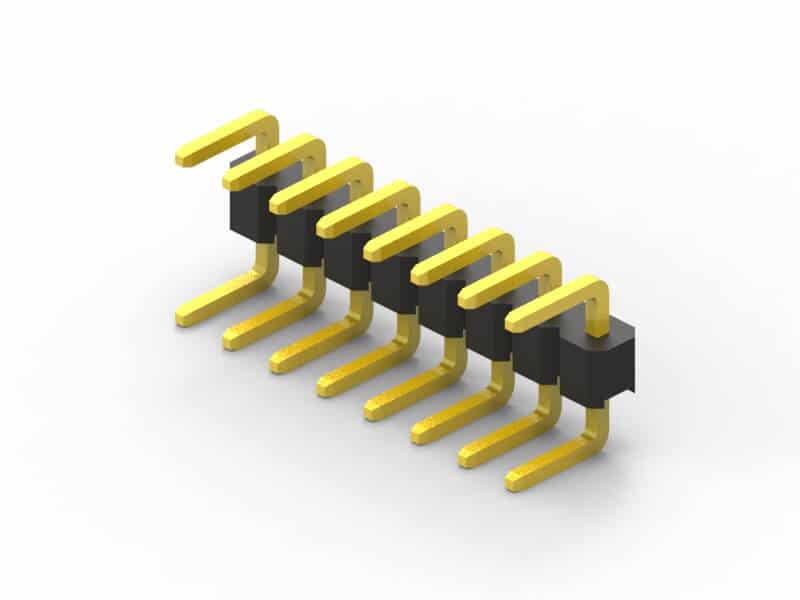

U-Shaped Pin Header

The U-shaped pin header offers a distinctive configuration for specific applications, ensuring optimal performance and connectivity.

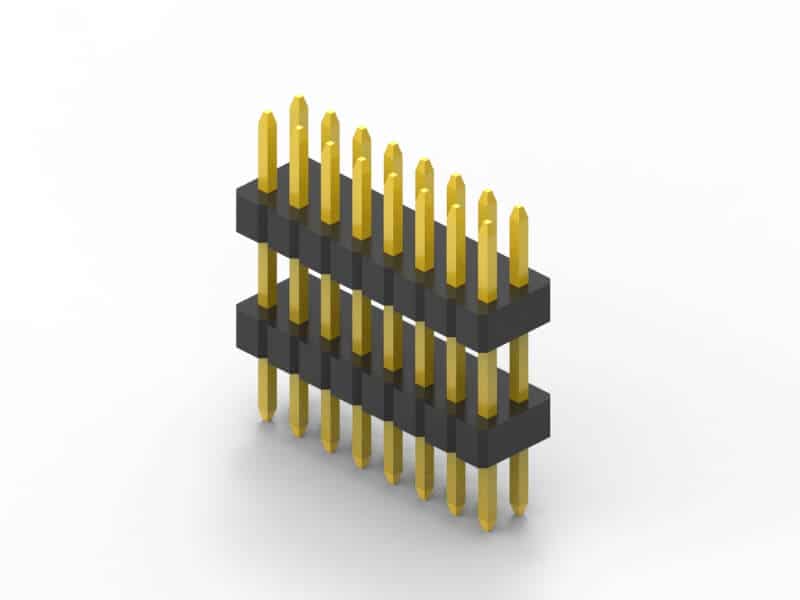

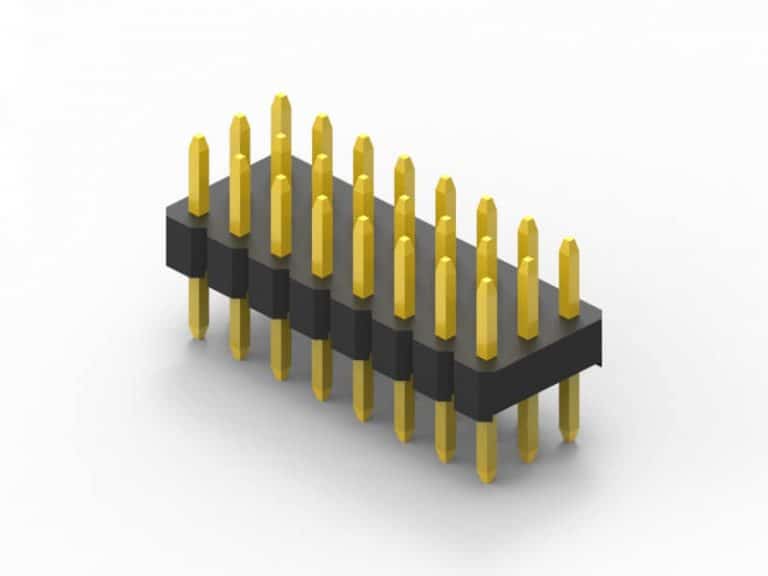

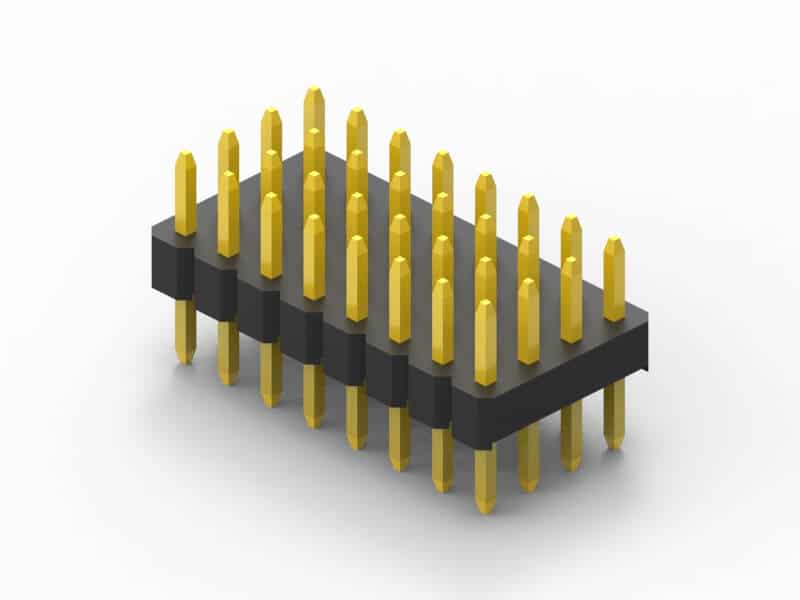

Multi-Row Pin Headers

We manufacture pin headers in three-row and four-row configurations, catering to complex and high-density applications.

Customization Capabilities

Scondar offers customization for various pitch sizes and mounting types. Our products include:

- Pitch Sizes: 1.0mm, 1.27mm, 2.0mm, and 2.54mm

- Mounting Types: Vertical and right-angle

- Technology Types: Through hole (TH/THT) and Surface Mount Device (SMD)

How to Customize Your Order

- Identify Your Requirements: Determine the specific shape, pitch size, and mounting type for your application.

- Contact Us: Share your custom requirements with us, detailing the configuration and any additional specifications.

- Collaboration with Our Engineers: Our expert engineers will work closely with you to create and confirm a sample that meets your exact needs.

- Sample Approval and Production: Once the sample is approved, we will proceed with mass production to ensure timely delivery and high-quality products.

Commitment to Quality

At Scondar, quality and customer satisfaction are our top priorities. We use state-of-the-art manufacturing processes and rigorous quality control measures to ensure that every product meets the highest standards.