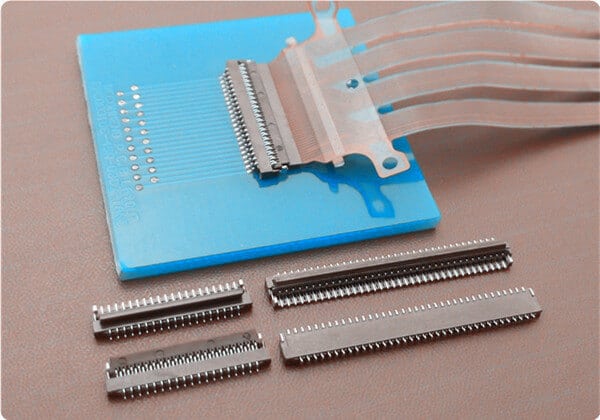

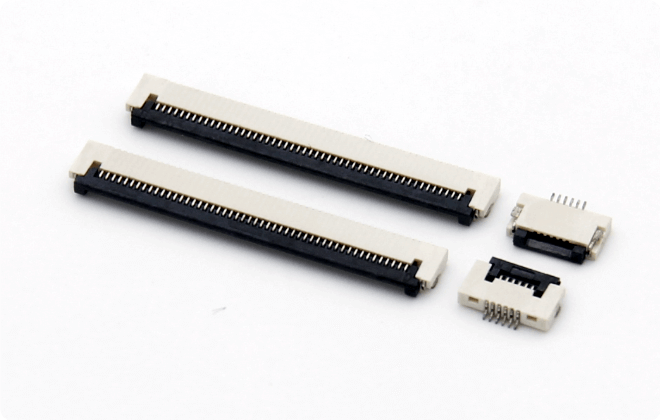

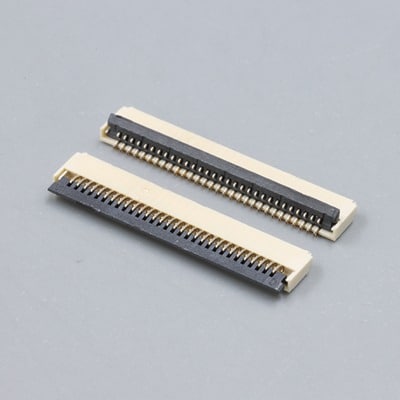

Scondar offers reliable FPC connectors & FFC Cable from 0.3mm pitch to 2.54mm pitch. Surface-mount, Through hole ( Vertical & Right-angle version).

We’d like to help you come cross reference to other Brand’s FPC connectors, then supply alternative one to you with good quality and competitive price.

Quality always comes first to us, free samples can be offered for quality evaluation or testing purpose.

Cross-reference by Pitch

FPC0520A1-xxPVSZS1

Circuits: 4 ~ 60

Height: 2.0mm

FPC0520A1-xxPVSFS1

Circuits: 4 ~ 60

Height: 2.0mm

FPC0520A1-xxPRSSS1

Circuit: 4 ~ 60

Height:2.0mm

FPC0520A1-xxPRSXS1

Circuit: 4 ~ 60

Height:2.0mm

FPC0512C2-xxPRSXG1

Circuit: 4 ~ 50

Height: 1.2mm

FPC0525D0-xxPVSZS1

Circuits: 10 ~ 40

Height: 4.0mm

FPC0520F2-xxPRSXS1

Circuits: 4 ~ 65

Height: 2.0mm

FPC0527G3-xxPRSXS1

Circuit: 4 ~ 80

Height: 2.5mm

FPC0525I2-xxPRSXG1

Circuit: 4 ~ 80

Height: 2.5mm

FPC0524L2-xxPVSZG1

Circuit: 4 ~ 80

Height: 2.4mm

FPC0524L2-xxPRSXG1

Circuit: 4 ~ 80

Height: 2.4mm

FPC0518M2-xxPRSXG1

Circuit: 4 ~ 60

Height: 1.8mm

FPC0525N2-xxPVSZG1

Circuit: 10 ~ 60

Height: 2.5mm

FPC0525O2-xxPRSXG1

Circuit: 10 ~ 96

Height: 2.5mm

FPC0510P3-xxPRSXG1

Circuit: 4 ~ 40

Height: 1.0mm

FPC0530Q2-xxPVSZG1

Circuit: 10 ~ 80

Thickness: 3.0mm

FPC0524R2-xxPRSXG1

Circuits: 4 ~ 60

Height: 2.4 mm

FPC0520T3-xxPRSXG1

Circuit: 4 ~ 80

Height: 2.0mm

FPC0520U2-xxPRSXHGT1

Circuit: 4 ~ 96

Height: 2.0mm

FPC0520V2-xxPRSXS1

Circuit: 4 ~ 80

Height: 2.0mm

FPC1034A0-xxPVZS1

Circuit: 3 ~ 35

Height: 3.4mm

FPC1034A0-xxPRZS1

Circuit: 3 ~ 35

Height: 3.4mm

FPC1030A0-xxPVSZS1

Circuit: 3 ~ 35

Height: 3.0mm

FPC1031A0-xxPRSSS1

Circuit: 3 ~ 35

Height: 3.1mm

FPC1031A0-xxPRSXS1

Circuit: 3 ~ 35

Height: 3.1mm

FPC1028B0-xxPVZS2

Circuit: 3 ~ 40

Height: 2.8mm

FPC1028B0-xxPRZS1

Circuit: 3 ~ 40

Height: 2.8mm

FPC1028B0-xxPVSZS1

Circuit: 3 ~ 40

Height: 2.8mm

FPC1028B0-xxPRSDS1

Circuit: 3 ~ 40

Height: 2.8mm

FPC1025D1-xxPVSZS1

Circuit: 4 ~ 40

Height: 2.5mm

FPC1025D1-xxPRSSS1

Circuit: 4 ~ 40

Height: 2.5mm

FPC1025D1-xxPRSXS1

Circuit: 4 ~ 40

Height: 2.5mm

FPC1027F3-xxPRSXS1

Circuit: 4 ~ 40

Height: 2.7mm

FPC1020G2-xxPRSXS1

Circuit: 4 ~ 40

Height:2.0mm

FPC12548A0-xxPVZS2

Circuit: 4 ~ 40

Hight: 4.8mm

FPC12548A0-xxPRZS2

Circuit: 4 ~ 40

Hight: 4.8mm

125A-NPW

Circuit: 4 ~ 60

Hight: 4.1mm

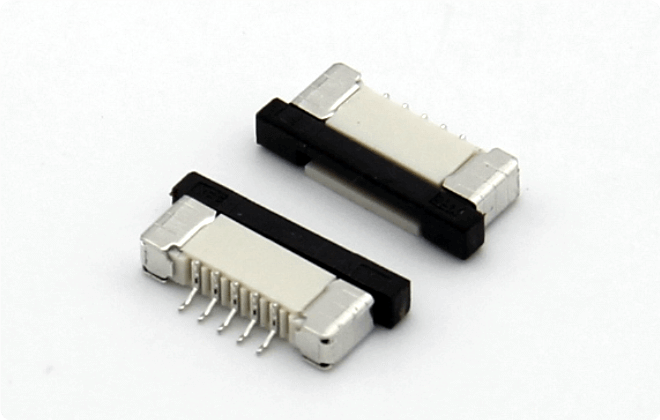

Exploring the Versatility of FFC and FPC Connectors in Modern Electronics

FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) connectors are common types of connectors in modern electronic devices, widely used in various products such as smartphones, tablets, laptops, digital cameras, and more. These connectors play a crucial role in achieving compact, lightweight, and efficient electronic products due to their unique structure and superior performance.

I. FFC Connectors

1. Overview of FFC

FFC (Flexible Flat Cable) consists of multiple parallel copper conductors embedded in a flat plastic strip. This design gives FFCs high flexibility, lightweight, thinness, and simplicity. They are typically used to connect printed circuit boards (PCBs) and other electronic components, suitable for applications requiring frequent bending or movement.

2. Features of FFC Connectors

– High Flexibility: FFC connectors can bend and fold freely in confined spaces, meeting various complex wiring needs.

– Lightweight Design: Due to their thin and lightweight structure, FFC connectors help reduce the overall weight of devices.

– High Reliability: FFC connectors offer stable conductivity and strong anti-interference capabilities, ensuring stable and reliable signal transmission.

– Easy Installation: FFC connectors are usually connected through simple plug-and-play mechanisms, making installation and maintenance very convenient.

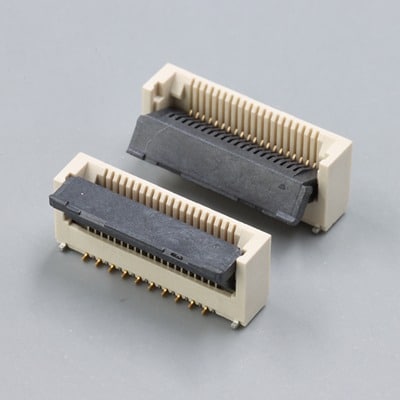

II. FPC Connectors

1. Overview of FPC

FPC (Flexible Printed Circuit) is a type of printed circuit board made of flexible materials. Unlike traditional rigid PCBs, FPCs have high flexibility and foldability, allowing wiring in complex spaces. FPCs are widely used in electronic products that require high-density and high-reliability wiring, such as LCD screens, camera modules, and other miniature electronic devices.

2. Features of FPC Connectors

– High Flexibility: FPC connectors can bend and fold freely in three-dimensional spaces, meeting various complex wiring needs.

– High-Density Wiring: FPCs allow for high-density, high-precision circuit designs, effectively improving the integration and performance of electronic devices.

– Lightweight and Compact: Made of flexible materials, FPC connectors are lighter and smaller than traditional connectors, making them ideal for lightweight, compact electronic devices.

– Durability and Reliability: FPC connectors have excellent bendability and high-temperature resistance, ensuring stable operation in various environments.

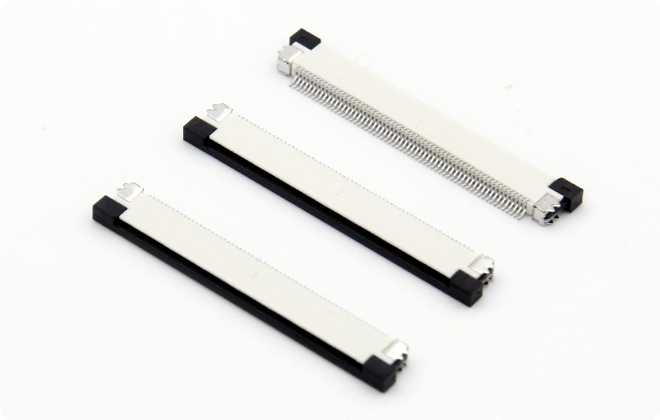

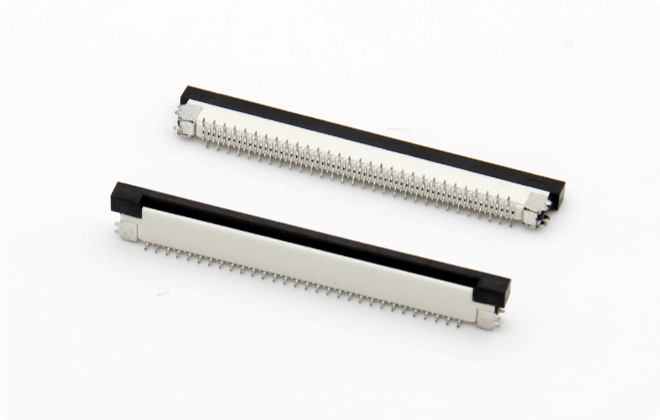

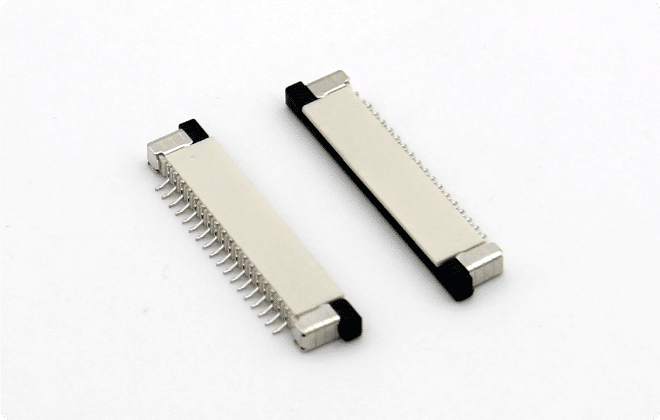

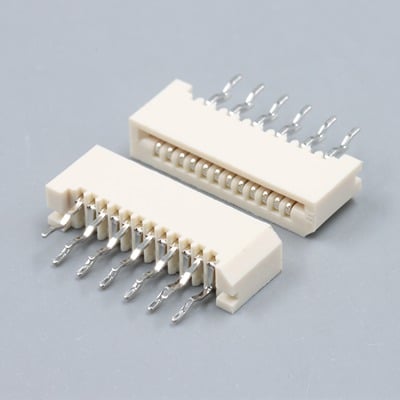

III. Types of FFC and FPC Connectors

1. Types of FFC Connectors

– By Connection Method:

– Plug-and-Play Connectors: Connected and disconnected by simple plugging, suitable for applications requiring frequent changes or maintenance.

– Crimping Connectors: Connected by mechanical crimping, typically used in applications requiring high reliability and long-term stability.

– By Contact Form:

– Single-Sided Contact: Conductive contacts on one side, suitable for simple circuit designs and larger spaces.

– Double-Sided Contact: Conductive contacts on both sides, suitable for high-density wiring and limited spaces, providing higher contact reliability.

– By Pitch:

– Large Pitch Connectors: Pitch usually above 1.25mm, suitable for higher current and signal transmission applications.

– Small Pitch Connectors: Pitch usually below 0.5mm, suitable for high-density wiring and miniature electronic devices.

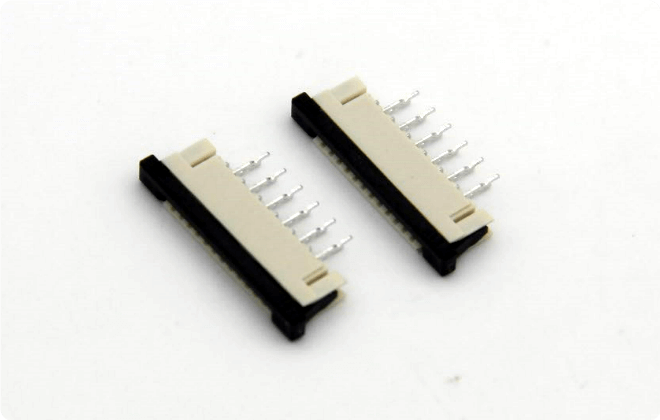

2. Types of FPC Connectors

– By Connection Method:

– ZIF (Zero Insertion Force) Connectors: Require almost no force for insertion or removal, ideal for applications with frequent connections, such as during development and testing.

– LIF (Low Insertion Force) Connectors: Require some force for insertion and removal, providing better contact reliability, suitable for most general applications.

– By Contact Form:

– Top and Bottom Contact: Contacts on the top and bottom sides, used for applications requiring double-sided contact.

– Front and Back Contact: Contacts on the front and back sides, used for specific wiring needs.

– By Locking Method:

– Slide Lock Connectors: Fixed by a sliding locking mechanism, suitable for high-reliability connections.

– Flip Lock Connectors: Fixed by a flip-lock mechanism, making installation and removal very convenient.

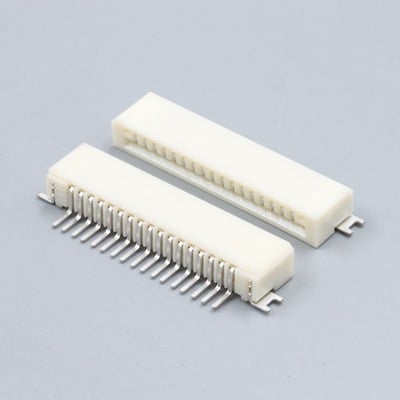

– By Pitch:

– Large Pitch Connectors: Pitch usually above 1.0mm, suitable for higher current transmission applications.

– Small Pitch Connectors: Pitch usually below 0.3mm, suitable for high-density and miniaturized circuit designs.

IV. Applications

1. Consumer Electronics

– Smartphone Connectors: Connecting displays, touch screens, camera modules, etc.

– Laptop Connectors: Connecting keyboards, touchpads, displays, etc.

2. Automotive Electronics

– Infotainment System Connectors: Connecting car displays and control modules.

– Sensor Connectors: Connecting various in-vehicle sensors and data acquisition modules.

3. Medical Devices

– Display Connectors: Connecting displays and control units in medical devices.

– Sensor Connectors: Connecting precision medical sensors and data processing modules.

V. Conclusion

FFC and FPC connectors, with their diverse types and superior performance, are widely used in various electronic products. Choosing the right type of connector can not only meet specific application requirements but also enhance the performance and reliability of electronic devices. With technological advancements, the design and functionality of these connectors will continue to improve, catering to more complex and demanding electronic products.

Questions? Write us!

Any Inquiry or question, Suggestion are welcome, the more details the message with, the more quickly response you get..

Contact Information

No. 1,Gaoda Industrial Park, Shuibu Rd

Fenggang, Dongguan, China (Mainland).