The 2.54mm male SMT (Surface Mount Technology) SMD (Surface Mount Device) pin header connector is a versatile and reliable component designed for a wide range of electronic applications. With a pitch spacing of 2.54mm (.100 inch), this connector offers secure and efficient connections in a compact form factor. Available in both single and dual row configurations, with pin counts ranging from 2 to 40 for single row and 4 to 80 for dual row, it provides flexibility to meet various design requirements.

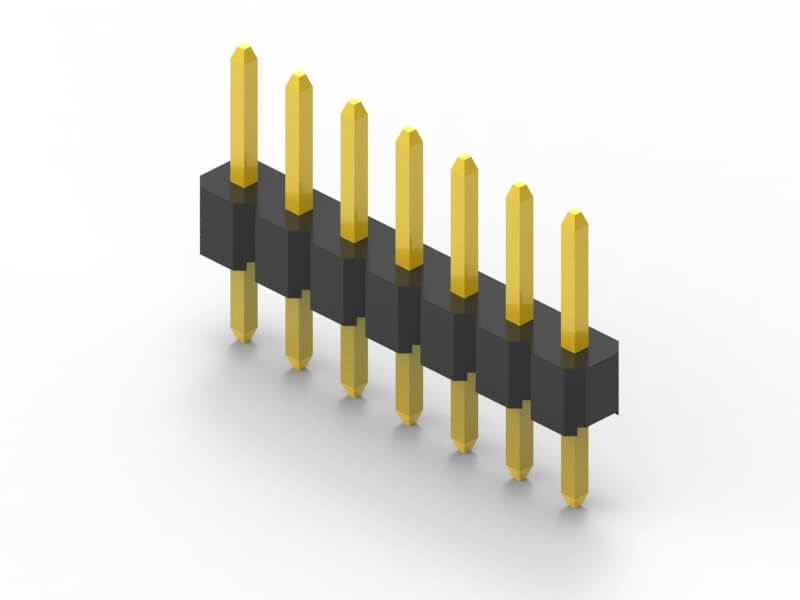

PH254H250SMT-1xxGA1301A

Row: Single

Circuits: 2 – 40 pins

Angle: Vertical

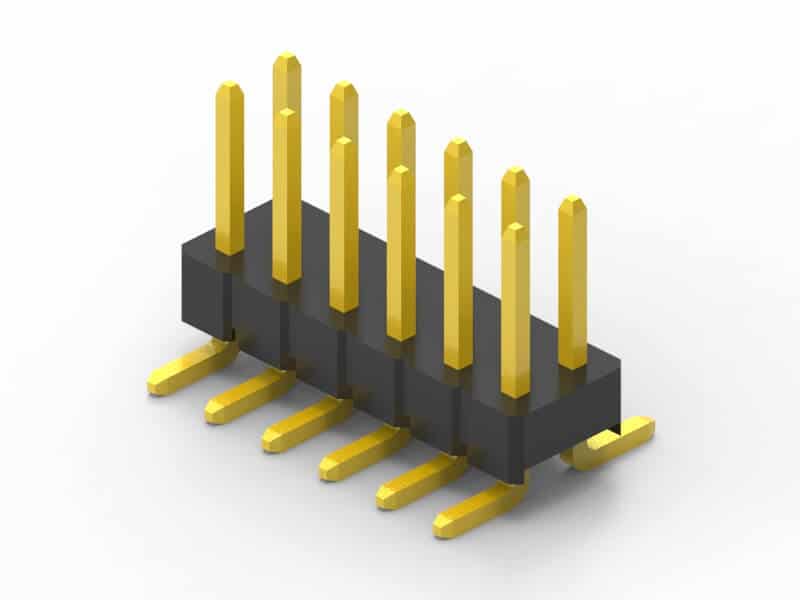

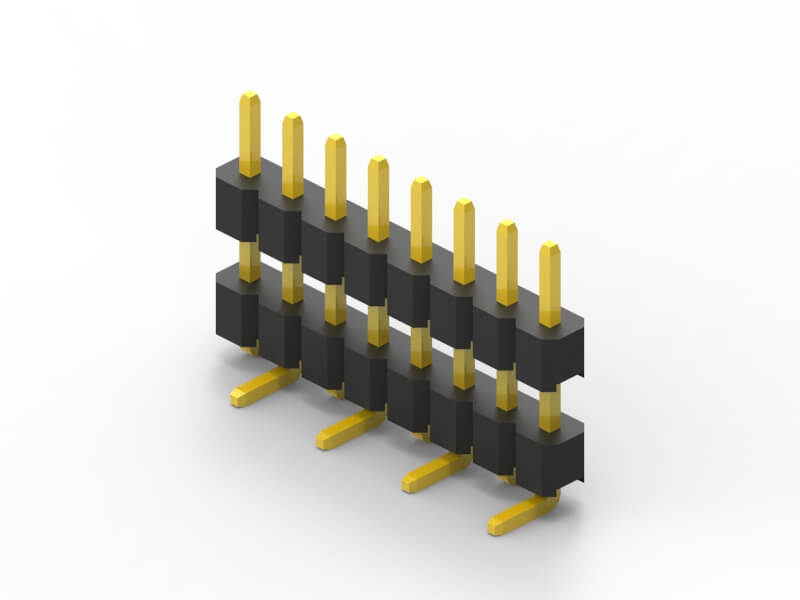

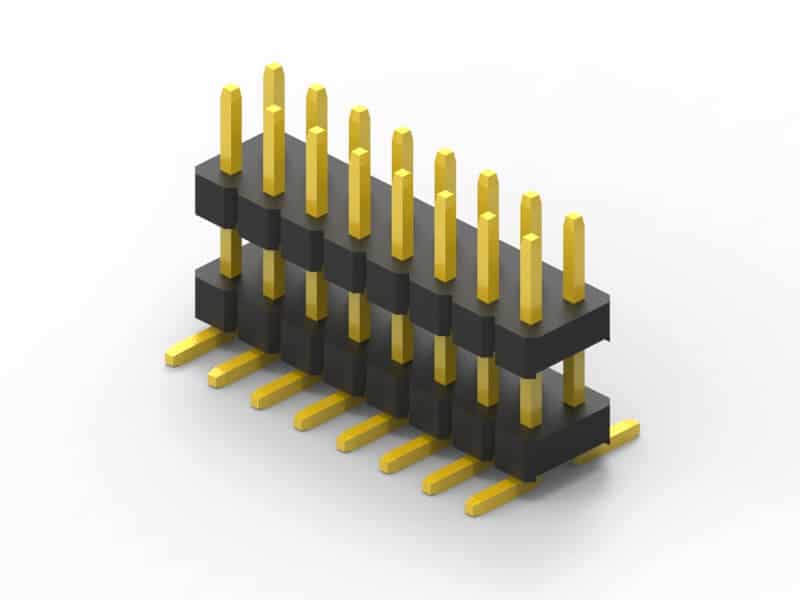

PH254H250SMT-2xxGA1301

Row: Dual

Circuits: 2 – 80 pins

Angle: Vertical

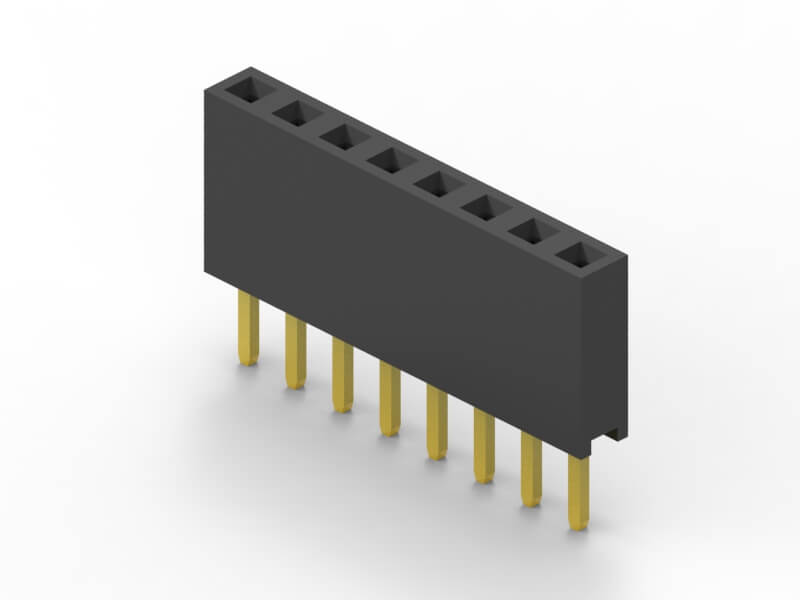

PH254DH250SMT-1xxGA1301A

Row: Single

Circuits: 2 – 40 pins

Angle: Vertical

PH254DH250SMT-2xxL1980GA1301

Row: Dual

Circuits: 2 – 80 pins

Angle: Vertical

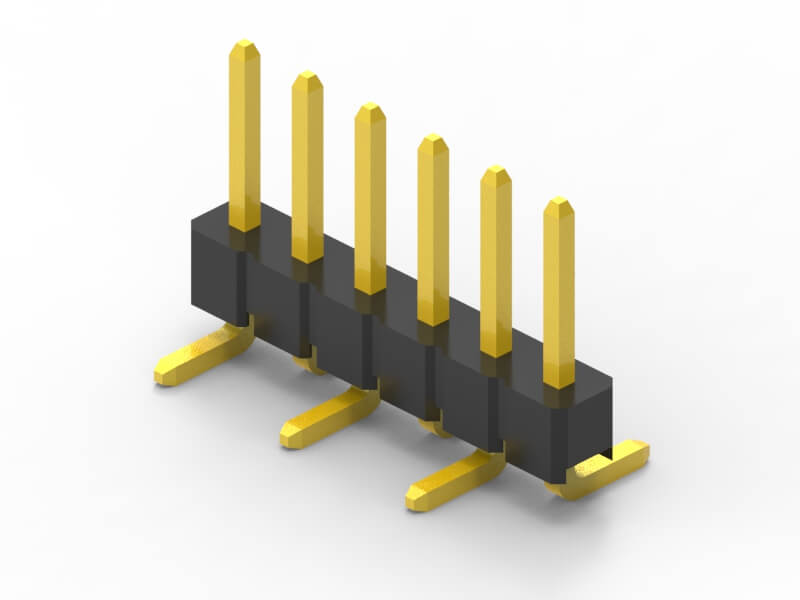

PH254H250RMT-2xxGA1301

Row: Dual

Circuits: 2 – 80 pins

Angle: Right-Angle

| General | Spec. |

|---|---|

| Product Name: | 2.54mm male SMT(surface mount) SMD pin header connector |

| Pitch(spacing): | 2.54mm (.100”) inch |

| Gender: | Male |

| Breakaway: | No |

| Number of Contact: | 2 – 40 pins (single row); 4 – 80 pins (dual row) |

| Number of Rows: | Single or dual |

| Orientation: | SMT(surface mount) Horizontal |

| locating peg | Optional |

| Material: | High Temperature Thermoplastic |

| Contact material: | Brass or Phosphor Bronze |

| Insulator material: | PA6T (Optional:LCP NA6T PA46 PA66) + UL94V-0 |

| Insulator color: | Black |

| Flammability: | UL94V-0 |

| Contact Plating: | Gold flash over 50μ” nickel or custom |

| Pin lengths: | Standard(PC= mm PA= mm) or Customizable |

| PC Tail Length: | Standard or Customizable |

| Packaging Type: | Tape&Reel or Tube |

| RoHS compliant: | Yes |

- Pitch (Spacing): 2.54mm (.100 inch) pitch spacing ensures compatibility with a wide range of electronic components and boards.

- Gender: Male connectors designed for secure mating with female counterparts.

- Number of Contacts: Available in configurations from 2 to 40 pins for single row and 4 to 80 pins for dual row setups.

- Rows: Options for single or dual row configurations to meet various application needs.

- Orientation: SMT horizontal orientation for surface mount applications, providing a low-profile connection.

- Locating Peg: Optional feature for precise placement and alignment during assembly.

- Material: Constructed from high-temperature thermoplastic for durability and performance under various conditions.

- Contact Material: Made from brass or phosphor bronze, offering excellent conductivity and reliability.

- Insulator Material: PA6T, with options for LCP NA6T, PA46, and PA66, all rated UL94V-0 for flammability.

- Insulator Color: Black, providing a standard and professional appearance.

- Flammability: UL94V-0 rating ensures safety in high-temperature environments.

- Contact Plating: Gold flash over 50μ” nickel, with custom options available, ensuring corrosion resistance and enhanced conductivity.

- Pin Lengths: Standard lengths for both PC tail and PA, with customizable options to suit specific application needs.

- Packaging Type: Available in tape & reel or tube packaging for easy handling and automated assembly.

- RoHS Compliance: Fully compliant with RoHS standards, ensuring environmentally friendly and safe components.

The 2.54mm male SMT SMD pin header connector is ideal for various applications, including:

- Consumer Electronics: Internal connections in devices like smartphones, tablets, and other portable electronics.

- Computer Hardware: Essential for motherboards, graphics cards, and other peripheral components requiring reliable internal connections.

- Automotive Electronics: Used in automotive control units, infotainment systems, and sensor modules.

- Industrial Equipment: Applied in industrial control systems, robotics, and automation equipment for robust connections.

- Medical Devices: Critical for medical instrumentation and diagnostic equipment where precision and reliability are paramount.

- Telecommunications: Employed in networking equipment, routers, and communication devices for stable and efficient connectivity.

High Density and Miniaturization

- Compact Design: SMT connectors are smaller than traditional through-hole connectors, allowing for more components to be placed on a PCB, leading to higher density and miniaturization of electronic devices.

- Double-Sided Assembly: SMT allows components to be mounted on both sides of the PCB, maximizing the use of available space.

Improved Performance

- Shorter Signal Paths: SMT components have shorter connections, which reduces signal transmission delays and resistance, enhancing circuit performance.

- Reduced Parasitic Effects: The smaller size and closer placement of SMT components reduce parasitic capacitance and inductance, improving high-frequency performance.

Enhanced Automation

- Suitable for Automation: SMT components can be placed using high-speed pick-and-place machines, increasing production efficiency and reducing labor costs.

- Reduced Manual Intervention: Automation minimizes human errors, resulting in more consistent and reliable products.

Cost Efficiency

- Material Savings: Smaller components require less material, which lowers the overall production cost.

- Efficient Production: Automated processes are faster and more efficient, reducing manufacturing costs and time.

Better Thermal Performance

- Improved Heat Dissipation: SMT components are in close contact with the PCB, allowing for better heat dissipation, which is crucial for high-power applications.

Design Flexibility

- Flexible Layouts: The compact size and light weight of SMT components allow for more flexible and optimized PCB layouts, enhancing the overall design and functionality.

Alignment with Modern Electronics

- Lightweight and Thin: SMT technology supports the development of lightweight and thin electronic devices, meeting the demands of modern consumer electronics.

- High Integration: SMT enables higher integration of functions, which is essential for complex electronic products.

The 2.54mm male SMT SMD pin header connector is a robust and adaptable component that meets the demands of modern electronic applications. Its combination of high-quality materials, flexible configurations, and compliance with safety standards makes it an excellent choice for designers and engineers seeking reliable connectivity solutions. Whether used in consumer electronics, automotive, industrial, medical, or telecommunications sectors, this connector provides the performance and dependability required for advanced technologies.