Wire Harness: Evolution of Electrical Connections

A wire harness is a systematic assembly of multiple wires organized together to transmit signals or electrical power within an electrical system. Its emergence signifies a significant advancement in electrical connection technology, providing more efficient and reliable solutions for a wide range of applications across various industries. This article will delve into the history, trends, functions, applications, structure, and manufacturing processes of wire harnesses.

Historical Development

The concept of wire harnesses can be traced back to the 19th century when electrical engineers began bundling wires to simplify the wiring process in electrical systems. However, the true development of wire harnesses began in the early 20th century within the automotive industry. With the proliferation of automobiles, the demand for electrical systems increased dramatically, rendering traditional individual wiring methods inadequate for complex connection requirements. Consequently, automotive manufacturers began adopting wire harnesses to bundle multiple wires together, improving installation efficiency and the reliability of electrical systems.

As electrical systems continued to evolve, the application of wire harnesses expanded into aerospace, electronics, household appliances, and various industrial sectors. Today, wire harnesses have become an indispensable component in a myriad of industrial applications.

Trends

With ongoing technological advancements, the development of wire harnesses exhibits several trends:

1. Lightweight and Compact Design: For applications requiring mobility and space savings, such as automotive and aerospace, lightweight and compact design are crucial trends in wire harness design. The use of lighter and more flexible materials, along with compact wiring methods, helps reduce system weight and volume.

2. Smart and Integrated Solutions: With the widespread adoption of smart technologies, wire harnesses are also evolving towards intelligent and integrated solutions. This trend involves incorporating smart components and technologies within the harness to enhance functionality, monitoring, and communication capabilities within the electrical system.

Functions and Applications

The primary function of a wire harness is to organize and bundle multiple wires together, facilitating the efficient transmission of signals or power within an electrical system. Wire harnesses find applications in various industries, including automotive, aerospace, electronics, and household appliances.

In the automotive sector, wire harnesses connect and distribute power between different components such as headlights, audio systems, and engine components. In aerospace, wire harnesses play a crucial role in connecting avionic systems and ensuring reliable communication between various aircraft components. The electronics industry utilizes wire harnesses for interconnecting complex electronic devices, and in household appliances, they contribute to the efficient operation of devices like washing machines and refrigerators.

Structure and Manufacturing Processes

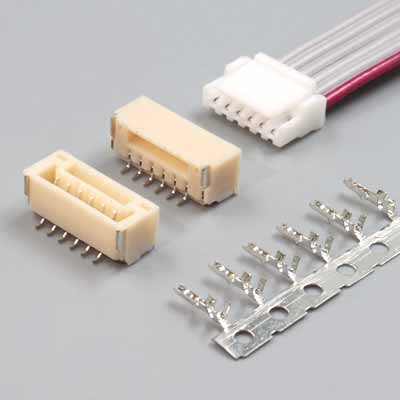

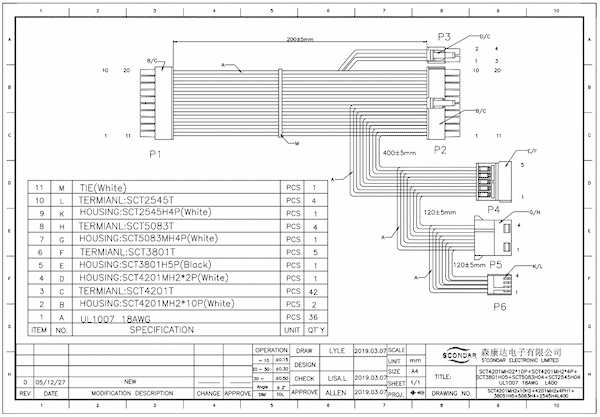

A typical wire harness comprises several components, including wires, connectors, terminals, sleeves, and protective coverings. The wires are organized based on their functions and connected to corresponding components. The entire assembly is then bundled together and secured using straps, cable ties, or protective sleeves.

The manufacturing process involves meticulous planning, cutting and stripping of wires, crimping or soldering connectors, and the assembly of the entire harness. Quality control measures, such as testing for continuity and insulation resistance, are essential to ensure the reliability of the final product.

With over 20 years of experience, Scondar stands as a leading custom wire harness manufacturer, providing dependable tailored services and a wide range of connector models and wires. Contact us for your customized solutions.

In conclusion, wire harnesses have evolved significantly from their early applications in the automotive industry to become integral components in various sectors. The ongoing trends towards lightweight, compact, smart, and integrated designs underscore the continuous innovation in wire harness technology, making them essential for the seamless functioning of modern electrical systems across diverse industries.