A wide variety of wire-to-board connector solutions that fit applications requiring like Molex KK 254 connector and Molex SL connector. You can require wire harness or custom cable assemblies too.

SCT2541 Series

Cross: Molex KK® 254 Connector Pitch: 2.54mm

SCT2542 Series

Cross: AMP 280358 Connector

Pitch: 2.54mm

SCT2544 Series

Cross: Molex SL™ Connector

Pitch: 2.54mm

SCT2545 Series

Cross: AMP 171822 Connector Pitch: 2.54mm

SCT2548 Series

Cross: AMP(TE) MTA-100 Connector

Pitch: 2.54mm

SCT2549 Series

Cross: Hirose HIF3B Connector

Pitch: 2.54mm

2.54mm (0.100″) Pitch Connectors

Scondar’s line of Reliable High-Density, Low-Profile Connectors

Scondar’s line of 2.54mm pitch connectors are durably made for high vibration environments, with a slightly taller header that is fully shrouded (can be unshrouded depending on electronic requirements), high-pressure housings and application of TPA enhancements. 2.54mm pitch connectors are more ruggedized and robust than other connectors with lower pitch values, but still maintains its properties for low-profile applications for signal and power transmission.

Scondar offers a wide variety of 2.54mm pitch connectors for wire-to-board solutions that fit the specs of branded and well-known electronic connectors such as Molex KK 254 connector, Amp, Dupont, and Molex SL connector. Customers may also be guided on wire harness and custom cable assemblies solutions too.

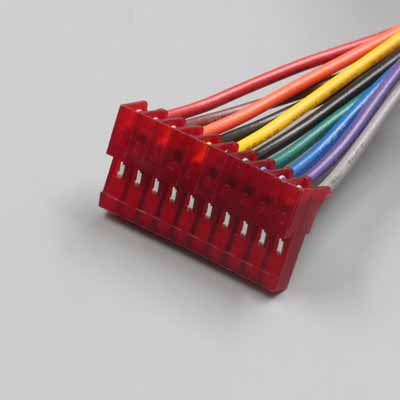

Molex KK® 2.54 Connector

KK 2.54mm Pitch is Molex’s tough electronic connector for PCB wire to board applications, with vertical headers and with a straight friction lock ensuring secure mating and retention when mated, making them suitable for harsh environments with a lot of movements. Housings are made from red UL 94V-0, which holds a well-balanced property of high strength, high rigidity, high toughness, abrasion resistance and good surface, making it the best choice for automotive and electrical/electronic industries.

KK 2.54 series is compatible with Cross Molex 2510 Connector Series. Furthermore, the connector delivers a good 3.0A AC/DC current and is available in 2 through 20 positions, accepting a range of 22 AWG to 28 AWG. It has a polarized mating feature that prevents any sort of mis-mating of harness to header.

Molex SL™ Modular Connector

The SL Modular Connector System is a 2.54 series connector which includes high-temperature LCP headers capable of reflow process enabling automation termination on PCB’s. This connector series comes with an integrated TPA lock and a CPA that allows positive-lock ensuring secure latching that will remain in place during operation and agitation of PCB

The Molex SL is compatible with C-Grid and KK products, making it a versatile solution to meet a wide range of design needs. This low-profile connector with polarized design and crimp-style lock is rated at 2.5A AC/DC, and can accomodate 22-26 AWG. The contacts are tin-plated phosphor bronze which can be of have dual row achieving multi-contact (up to 40 contacts), with a 30% higher density to sustain mechanical stress in the mounting area.

AMP543 2.54 Pitch Connector

AMP 2.54 Pitch connector is applicable for IDC receptacle mass termination of wires in a wide variety of applications. These connectors are loaded with dual beam cavities for IDC contacts that eliminate the need for stripping the wire. Designed to be piled in stacks, these have molded housing ribs preventing reverse mating and are completely polarized. Its lubricated contacts are part of its protection against corrosion.

With a variety of the number of contacts to choose from (2 through 32 positions), delivering 2.5 A per contact for AWG #28 to #30, these 2.54 AMP connectors are optimal for mass termination. It is widely used in the automotive industry for chassis systems, driver information, security systems and body systems. They are further used in the electronic industries for desktop PC’s, notebooks and servers as a valuable electronic component.

AMP 280358 Housing

TE’s AMP 280358 is a two-way receptacle housing for 2.54mm pitch connectors made of thermoplastic with copper allow contact base. Features for this housing include a friction latch which snaps snuggly with its mated component and also a housing material which is UL94V-1.

AMP 171822 Housing

TE’s AMP 171822 is a 2.54mm pitch, single row/dual row, EI series housing for use with 170262 & 170263 contacts. It is made of thermoplastic with copper allowing contact base. A locking protrusion is placed on the center of the housing allowing ease of maneuver of the connector with the housing and easy one-step assembly.

It is specially made for 2.54mm pitch connectors with current rating of 3.0A, operating at 250 VAC, 350 VDC voltage.

Dupont 2.54 Connector

Dupont 2.54 mm Pitch connector is a low profile connector delivering 3.0A current for WG #22 to #28, available in 1 to 40 2*1 to 2*40 positions suitable for either power transmission systems or chassis wiring. Scondar offers a crimp style lock and a configuration which prevents users from inverted insertion.

Dupont 2.54 connector is has a flexible terminal strip and board stackers for stacking. It is available as either with a shrouded or unshrouded header, with configurations for through-hole, SMT or mixed technology and press fit. It is also available for either vertical, perpendicular or coplanar mating and offered in a wide variety of standard options such as polarization, locking clips and alignment pins.

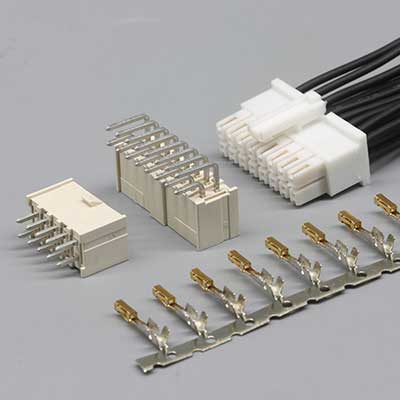

Components of 2.54 mm Connectors

Housing

The connector housing provides electrical insulation between the contacts and between the contact and the external circuit. Dielectric Withstand Voltage (DWV) usually verifies the voltage rating of the connector.

A well-designed housing holds the connector contacts providing trouble-free mating and unmating. Spacing between the contacts is also fixed by the housing. Creep (electrical tracking distance over surfaces) and clearance (linear “line‐of‐sight” distance) is also maintained by the housing.

The housing is smartly engineered to allow efficient signal and power transmissions and at the same time, provide some level of environmental protection to the electrical contacts.

Scondar manufactures the housing from Nylon 66, which is a material highly used when high mechanical strength, rigidity, stability is needed under varying temperature changes. That is why all Scondar connectors can withstand a wide temperature range from between -35 deg C to 85 deg C.

Furthermore, the housing is molded in UL94V0 natural ivory and is RoHS compliant, which has passed the flammability test for electronics and as such, the connectors produced by Scondar are ideal in rugged electronic devices, sustaining high environmental stresses. Also, the housing may be available with or without protrusions, depending on customer needs and specifications.

Header

The header contact is made up of copper alloy, tin plated over a phosphor bronze material.

Terminal

Scondar’s connector terminals are made of tin-plated, phosphor bronze. The terminals have a thickness range of 0.12mm-0.15mm depending on the 1.0mm connector type and standard reels are 20,000 pieces per reel.

Tin-Plating

Tin-plating is less costly and generally for applications carrying more than 0.5A, where high cycling is specified.

Phosphor bronze

Phosphor bronze is stronger than brass and has better spring properties that lends itself useful in smaller contacts that can best leverage its mechanical properties. This material is commonly found in small and medium‐pitch signal and moderate‐power connectors.

Quality Assurance of Components

How Scondar makes 100% Reliable and Compatible Connectors

Quality is at the heart of Scondar’s standards where facilities are UL & ISO 9001:2008 certified. Scondar ensures materials and components always meet their needs with UL file number and ISO certification.

Assemblies are 100% tested guaranteeing reliability and compliance, a variety of appropriate tests are applied depending on cable assembly type. Examples are: Short or open circuit, intermittent circuit, mis–wiring. Hi-Pot, static load for strain relief, bending test, crimp pull off force, contact to housing retention force and plastic hardness.

Individual discrete wires are stripped of insulation, crimped and then inserted into female housing to complete the assembly. The completed assembly mates with a male PCB header, which offers options for locking, latching and polarised connectors.

Wiring Harness/Cable Assembly

In many cases, a wire harness or cable assembly is needed to compress masses of wires stretching over a distance. By binding these wires into cable assemblies, these cables can be better secured against the adverse effects of vibrations, abrasions, and moisture.

Scondar’s wires are produced into a non-flexing bundle, for space optimization and safety purposes, where installation time can be decreased and the process of installing electronic circuits in standardized. Their positive locking latch provides only a slight increase in disengagement force of the terminals.

Blind-mating solutions implemented in the connectors allow engagement of the connector system without visual alignment. Scondar connector series has a heavy-duty, shrouded design providing positive polarization to aid in blind mating applications. Scondar meets close adherence to the connector system specifications for blind-mating solutions for a more efficient connecting system and interference capability.

Wire Gauge

For 2.54 mm connectors, wire gauges that can be accommodated with the rated current and voltage is between AWG #22-28. The following table represents the specs of these wire gauges.

| AWG | Conductor Diameter in mm | Conductor Cross Section mm2 | Maximum amps for chassis wiring | Maximum amps for power transmission |

|---|---|---|---|---|

| 22 | 0.64516 | 0.327 | 7 | 0.92 |

| 23 | 0.57404 | 0.259 | 4.7 | 0.729 |

| 24 | 0.51054 | 0.205 | 3.5 | 0.577 |

| 25 | 0.45466 | 0.162 | 2.7 | 0.457 |

| 26 | 0.40386 | 0.128 | 2.2 | 0.361 |

| 27 | 0.36068 | 0.102 | 1.7 | 0.288 |

| 28 | 0.32004 | 0.080 | 1.4 | 0.226 |